A Reliable Partner for Your Precision Tooling & Manufacturing Needs

Customer service and quick response remains our true focus

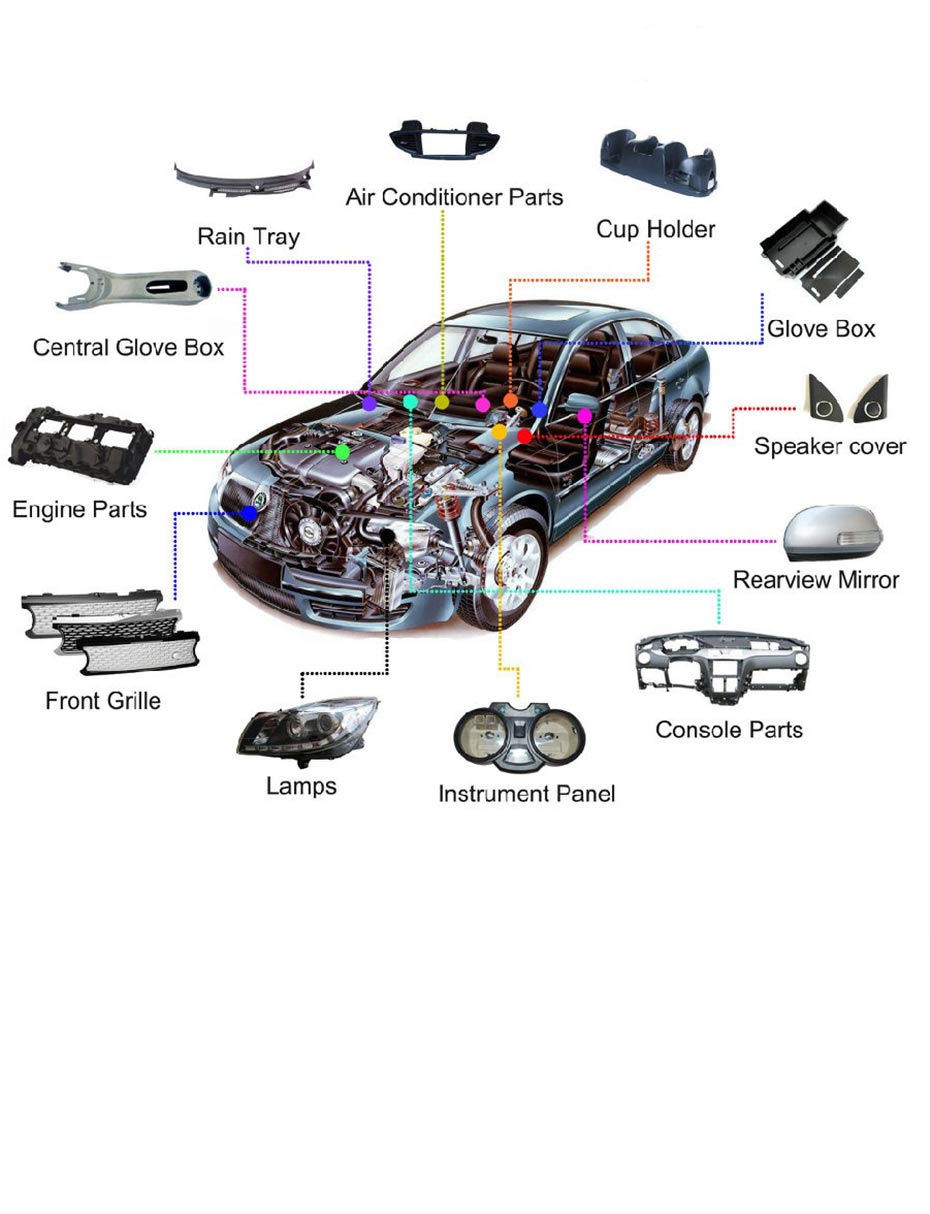

Wocax is rich experienced in multi-shot, lighting, console, door panel, air vent, grille, all types of interior & exterior automotive molds.

Wocax Packaging Division is specialized in high-cavitation, shortest cycle time and long lifetime molds for caps, closures, thin wall IML containers, cosmetic and personal care since 2011.

Wocax Packaging Division has also designed and manufactured high performance injection molds for dialysis devices, disposable syringes, regulators, test tubes, etc.

Wocax own more than 20 molding machines in house ranging from 30T to 1000T, including Milacron, Sumitomo (SHI) Demag, and Haitian brands.

With more than 20 years experience in precision mold making, Wocax provides customers with prototype and production molds that range in all sizes up to 2.5 meters. The customers we served are all over the world including international companies like Porsche, Bentley, Mercedes-Benz, BMW, VW, Toyota, Honda, Ford, etc.

Taking advantage of our comprehensive industry know-how affords your business core competencies.

Fast cycle time 4s

Thin wall 0.3mm

High precision 2μm steel accuracy

High productivity 24, 32, 64, 96, 128 cav

Long lifetime 5,000,000+ cycles

Trust is probably the most valuable currency in the healthcare industry and it doesn’t come easy. At Wocax, we understand that we have a responsibility not just to our customers but to society at large. We’re committed to providing high quality products. We use original material such as ASSAB / Uddeholm, BÖHLER, SCHMOLZ + BICKENBACH & Finkl Steel, Hasco/Meusburger standard parts, Husky hot runner, FDA approved resins, etc.

With 100,000 class clean room and more than 35 sets of high speed electric injection machines. We work 7/24. Here your concept and design will be turned into a ready to sale product.

Scientific molding

High cavitation mold and fast cycle time

24 hour maintenance expert support

Spare part inventory

Strong backup from internal tool shop

Founded in 2004, Wocax is now an ISO9001:2016, IATF 16949:2016, ISO13485:2016 certified manufacturer with 260 employees and modern facilities. We offer full service for Automotive, Electronic, Household, Packaging and Healthcare industries from plastic injection mold making to molding production and final assembly. We consider ourselves as a partner you can work with to find the optimum solution. You can expect quick turnaround time, top quality and attentive service all here.