Our Product & Services

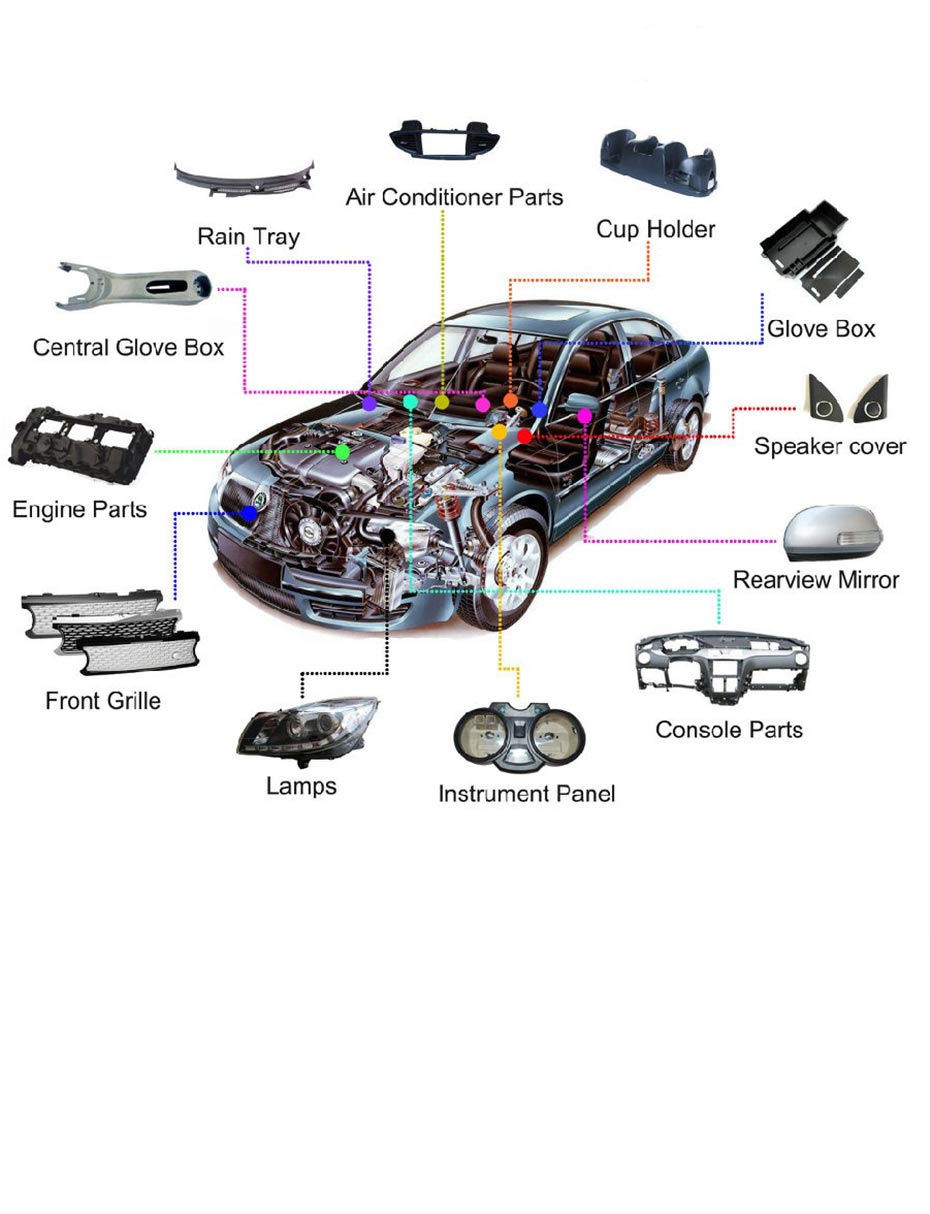

AUTOMOTIVE

Wocax is rich experienced in multi-shot, lighting, console, door panel, air vent, grille, all types of interior & exterior automotive molds.

PACKAGING

Wocax Packaging Division is specialized in high-cavitation, shortest cycle time and long lifetime molds for caps, closures, thin wall IML containers, cosmetic and personal care since 2011.

HEALTHCARE

Wocax Packaging Division has also designed and manufactured high performance injection molds for dialysis devices, disposable syringes, regulators, test tubes, etc.

INJECTION MOLDING

Wocax own more than 20 molding machines in house ranging from 30T to 1000T, including Milacron, Sumitomo (SHI) Demag, and Haitian brands.